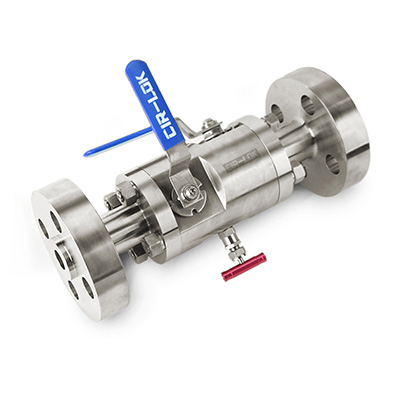

IntroductionCIR-LOK unique combination of double block and bleed valve systems enable a smooth transition from the process piping systemto instrumentation, providing fewer potential leak points, lower installed weight, and a smaller space envelope. Block and Bleed Valves are designed for process piping isolation points,direct mount to instruments,close coupling of instruments,double block and bleed isolation,vents and drains

FeaturesMaximum working pressure up to 10000 psig (689 bar)Working temperature from -10℉ to 1200℉ (-23℃ to 649℃)Complementing the existing one-piece range, flange to flange bolted construction DBB valves available in sizes from 1/2 to 2Designed according to ASME VIII & ANSI B16.34Weight, space and cost saving over traditional designsComplete traceability of materials

AdvantagesWeight, space and cost saving over traditional designsLive-loaded stem seal ensures positive sealing across the pressure and temperature range.. Internally assembled stem protects against blowout.Antistatic designChemical and physical material certifications availableLive-loaded seats maintain system seal through changes in pressure and temperatureCavity pressure relief prevents overpressurization from thermal expansion of system media when the valve is closedReduced fugitive emissions

More OptionsOptional material 316 stainless steel, carbon steel, Alloy 20, Alloy 400, Incoloy 825, and duplex stainless steel materialsOptional Full-bore Series,Reduced-bore SeriesOptional for sour gas service